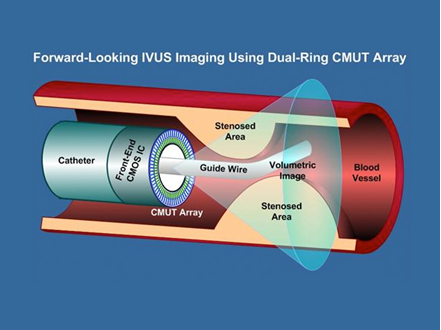

Intravascular ultrasound (IVUS) is a non-invasive medical imaging method that allows imaging of arteries from inside-out, providing critical information for coronary artery disease diagnosis and cardiovascular intervention guidance. IVUS images are obtained using miniaturized ultrasound imaging probes mounted on the tip of a catheter, which are then inserted into the artery using a guidewire. The imaging probes must operate at high frequencies to obtain sufficient resolution, with commercial IVUS devices operating in a range from 20 MHz to 60 MHz. As a result, the size of IVUS transducer elements must be in the order of tens of microns to avoid grating lobes, making fabrication of IVUS imaging probes challenging. The small transducer element sizes also increase its electrical input impedance, making the imaging probe more sensitive to parasitic components. Therefore, to obtain an image of sufficient contrast, close integration between front-end electronics and the transducer array is required, further complicating the imaging probe miniaturization.

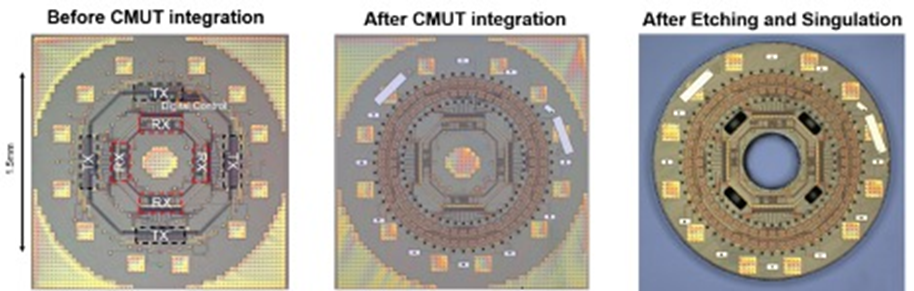

Capacitive micromachined ultrasonic transducer (CMUT) technology is especially well suited to address the challenges of IVUS applications. CMUTs are MEMS based ultrasonic transducers, in which acoustic signals are generated and received through the flexural deformation of an array of membranes. As such, CMUTs naturally have an acoustic impedance matched with the medium eliminating the need for acoustic matching layers and intrinsically increasing the transducer bandwidth. CMUT arrays utilize well-established microfabrication techniques, allowing fabrication of densely populated transducer arrays of very small element sizes and complex array structures with relative ease. Moreover, by limiting the processing temperature CMUT arrays can be fabricated directly on top of electronic circuitry, enabling monolithic integration to front-end electronics and fabrication of fully integrated single-chip systems, which we call CMUT-on-CMOS systems.

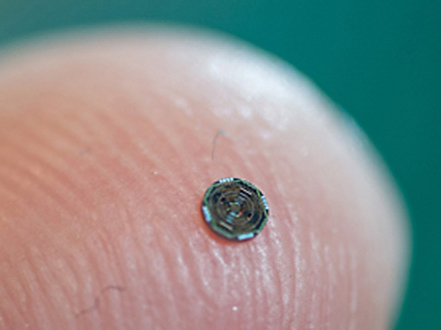

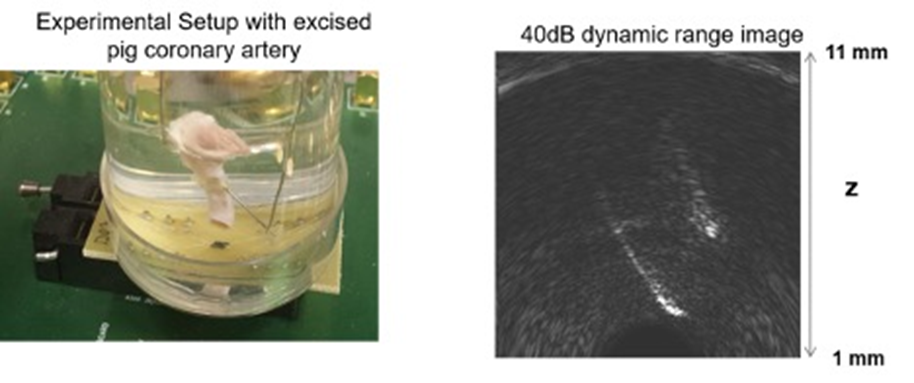

We have successfully designed and fabricated forward looking volumetric IVUS imaging CMUT-on-CMOS systems using a low temperature CMUT-on-CMOS fabrication approach developed by our group. The developed monolithic fabrication approach allows for extremely tight integration between transducer elements and CMOS circuitry with only a few additional fabrication steps. The functionality of the fabricated IVUS system-on-a-chips is demonstrated through imaging experiments.

Associated students: Evren Arkan

References

[1] J. Knight, J. McLean, and F.L. Degertekin, “Low Temperature Fabrication of Immersion Capacitive Micromachined Ultrasonic Transducers on Silicon and Dielectric Substrates,” IEEE Trans. on UFFC, 51, pp. 1324-33, 2004 (IEEE UFFC Society Outstanding Paper Award).

[2] J. Zahorian, M. Hoffman, T. Xu, G. Gurun, S. Satir, M. Karaman, and F.L. Degertekin “Monolithic CMUT on CMOS Integration for Intravascular Ultrasound Applications,” IEEE Trans. on UFFC, 58, pp. 2659-2667, 2011.

[3] G. Gurun, C. Tekes, J. Zahorian, T. Xu, S. Satir, M. Karaman, J. Hasler and F.L. Degertekin, “Single-chip CMUT-on-CMOS front-end system for real-time volumetric IVUS and ICE imaging.,” IEEE Trans. on UFFC, 61, pp. 239-50, 2014.

[4] J. E. Arkan and F.L. Degertekin, “Analysis and Design of High Frequency 1-D CMUT arrays,” IEEE Trans. on UFFC, 66, pp. 382-393, 2019.