Optical Microphone

Microphones come in many different variations and are often classified in terms of their transudation mechanisms and their directional properties. The focus of current research combines an optical displacement detection scheme with a unique design for achieving directionality. The diffraction based optical detection method has been incorporated into this directional microphone using an interdigitated finger design. The design for directionality on the other hand is based on the intertympanal mechanical coupling of a parasitoid fly, Ormia ochracea. Although the noise floor of a directional microphone is inherently higher than that of an omni-directional microphone, the high sensitivity of the optical detection method promises to minimize this noise floor. Additionally, because directional microphones are able to attenuate off-axis sound sources, these microphones have excellent potential for applications such as hearing aids. Miniaturization of the optical microphone is realized by using extremely small light sources in the form of vertical cavity surface emitting lasers (VCSELS) and photodiode arrays. These commercially available optical elements measure only several hundred microns in their largest dimensions and require minimal power. Using innovative techniques such as pulsed VCSEL modulation, it is possible to operate these optical microphones under even smaller power budgets. One goal of this research is to use these small optical components to assemble multiple optical microphone elements together to form acoustic arrays, which can detect frequencies of interest as well as perform source localization algorithms without significant sound field interference.

The basic operating principle of the diffraction based optical displacement detection scheme is shown above. In this configuration, the top electrode is the microphone diaphragm which serves as a backplate and the bottom electrode is the diffraction grating fabricated on the silicon substrate. Both these electrodes are electrically conductive and optically reflective. The silicon substrate is etched from the backside so that there is an optical path to reach the reflective diffraction grating. In this configuration the diffraction grating is fixed to the substrate and the microphone diaphragm is moving with the incoming sound wave. However, moving grating with fixed reflective backplate is also an acceptable design. The overall system forms a phase sensitive diffraction grating.

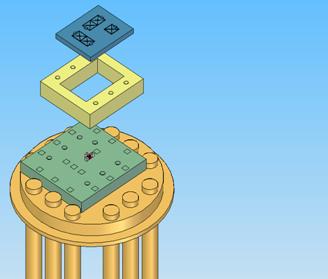

In order to make the testing of the optical microphones more feasible, integration of microphone structures with the optical components and electronics is done. The details of the packaging and the final integrated microphone with the electronics can be seen from the figure above. In the integration step, because of the size requirements, vertical cavity surface emitting lasers (VCSEL) are used as a light source and small photodiode bare chips used for the detection. All the components are integrated on a transistor outline header (TO-header) in order to minimize the packaging effects. The integrated optical microphone structure has the same architecture as the current commercial inch measurement microphones have.

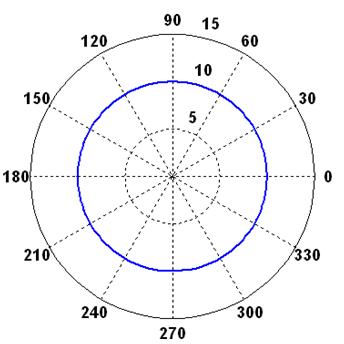

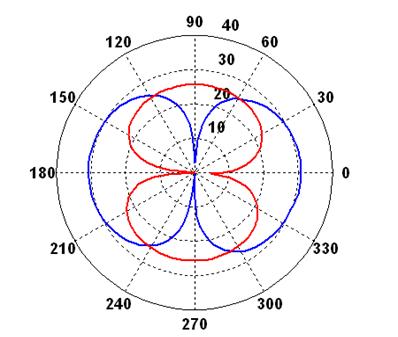

After integrating the optical microphones, characterization and testing of the microphones are done in the anechoic chamber facility of Georgia Institute of Technology (Integrated Acoustic Labs). The above plots show the measured directionality responses of the optical omnidirectional and gradient microphone. As expected the gradient microphone shows the Figure-8 pattern. The red and blue curves on the right figure show the directionality of the two gradient microphones on the same chip which are placed perpendicular to each other. It can be seen from the figure that one of the microphone has a sensitive direction at 0 degrees while the other has at 90 degrees.

People: Fred Banser, Baris Bicen, Kamran Jeelani, Sunny Jolly

Collaborators: Dr. Ron Miles (Suny at Binghamton), Dr. Gert Cauwenberghs (UCSD)

Funding: National Institute of Health, Catalyst Foundation